Auckland has just been given its first look at the country’s most advanced bus charging facility, with the completion of major upgrades at Kinetic’s Glenfield Bus Depot.

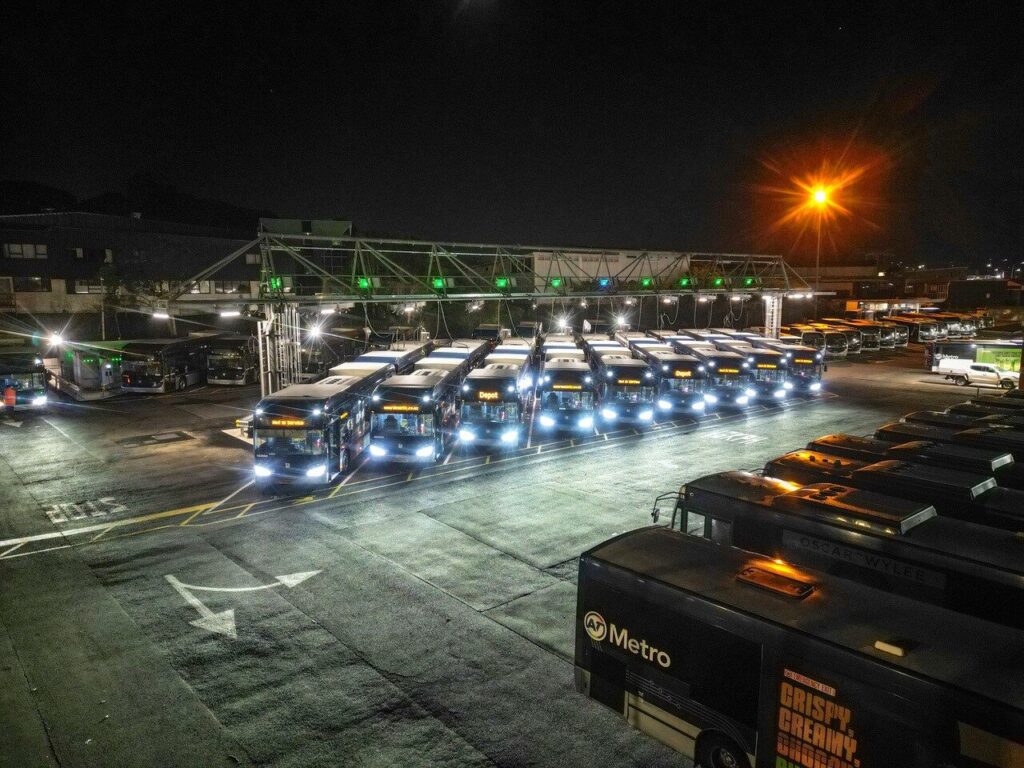

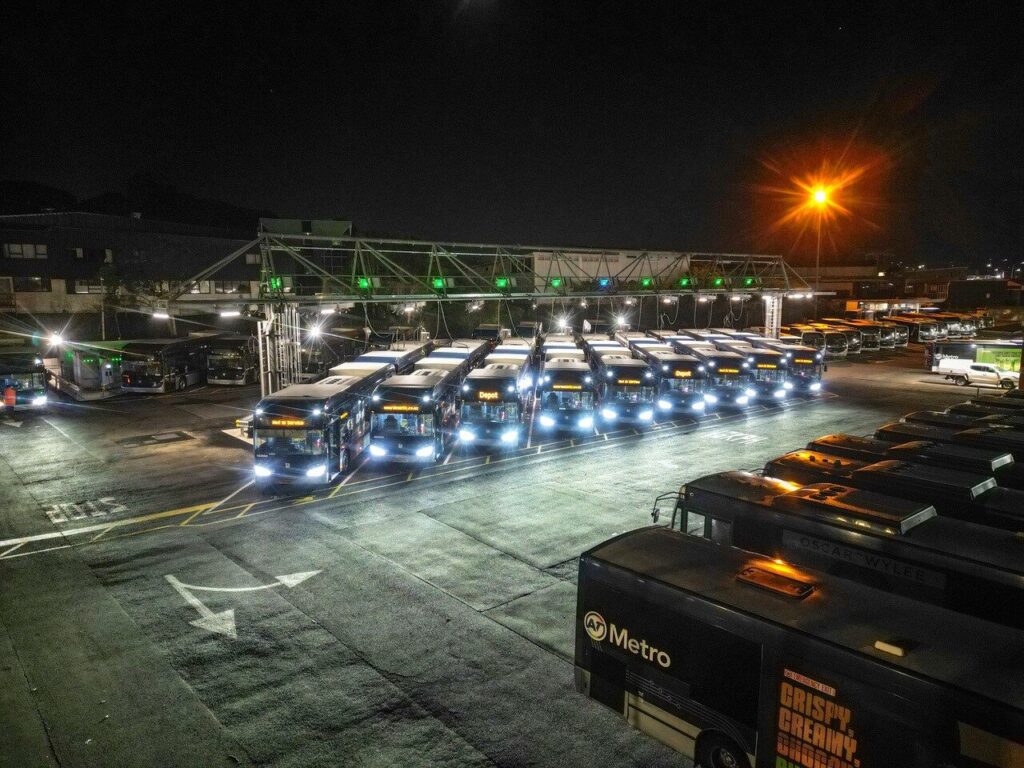

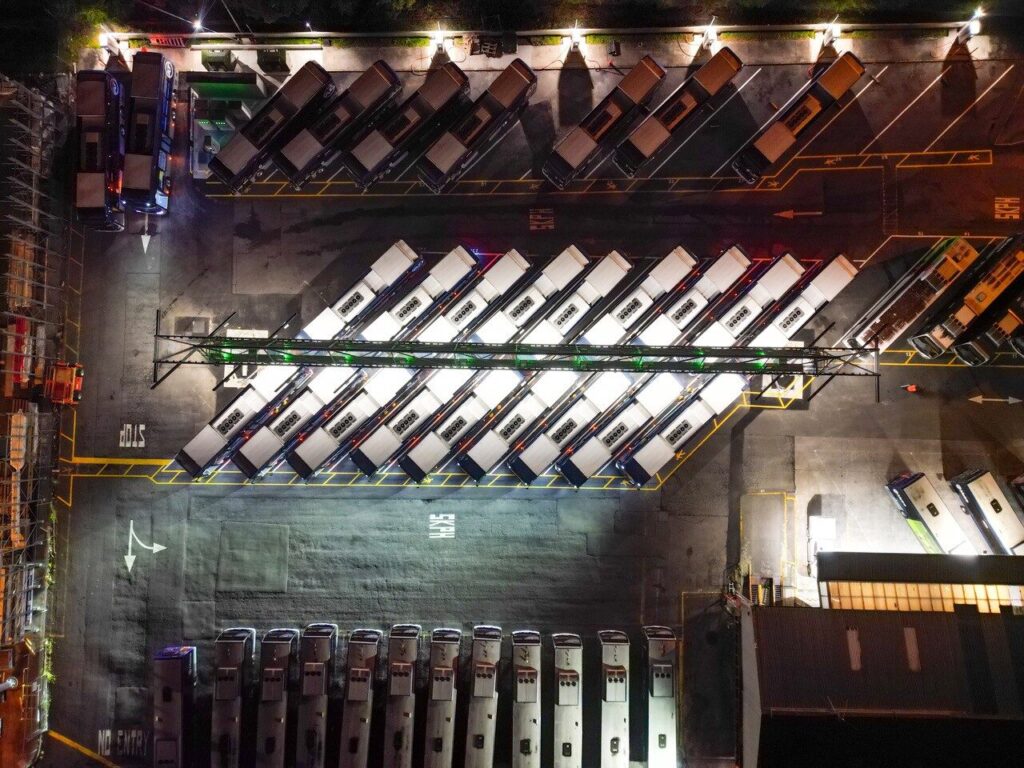

The project, led and delivered by Kinetic, in partnership with Auckland Transport, ABB and Singer Electric, introduces New Zealand’s first large-scale overhead gantry charging system, capable of powering up to 20 electric buses at once — and up to 34 buses on the site overall.

The upgrade will support the rollout of 31 new zero-emission buses (ZEBs) on Auckland’s North Shore, making the Glenfield depot the largest and most space-efficient charging site of its kind in New Zealand. With 174 electric buses now operating across five electrified depots, Kinetic operates around 68% of Auckland’s zero-emission bus fleet.

Calum Haslop, Managing Director of Kinetic New Zealand, said the project reflects a long-term commitment to smarter, cleaner transport.

“The introduction of 31 new zero-emission buses to our Glenfield depot marks another important step in the evolution of Auckland’s public transport network. What makes this milestone particularly exciting is the integration of an overhead gantry charging system, which allows us to charge multiple vehicles efficiently, safely, and at scale within our existing depot footprint.”

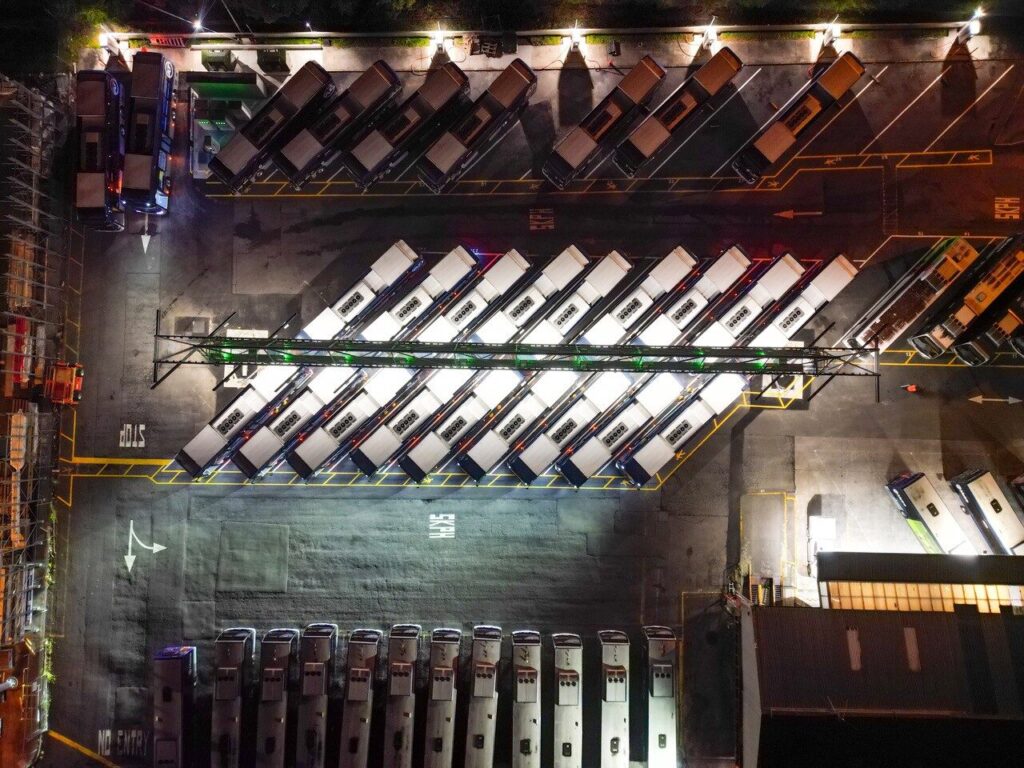

The gantry stretches across the depot, with 20 overhead charging outlets suspended from its steel frame — powered by five ABB HVC 360 power cabinets, each able to deliver up to 360 kW across four connections.

Rather than lining up nose-to-tail, buses are parked diagonally beneath the gantry — a layout carefully designed to match their wide turning arcs and ensure smooth entry and exit. Drivers pull down a retractable lead to connect, keeping cables off the ground and maximising safety.

Singer Electric played a central role at Glenfield, delivering the installation of all electrical infrastructure and the associated civil works for the gantry structure. Their expertise and commitment were critical in bringing such a complex brownfield installation to life.

“It was a project with a lot of moving parts,” said Jason-Lee Wood, Project Supervisor at Singer Electric. “Our role was to coordinate the electrical components of the project, anticipate issues, and make sure everything from transformer placement to gantry positioning came together. That’s what we do best — ensuring technology can actually work in the real world,” he says.

Jason added that the gantry solution is already proving itself.

“The gantry is a fantastic structure. It saves ground space, reduces wear on charging cables, and makes life easier and safer for drivers. We templated every piece of equipment before construction to make sure it all fit within the depot’s tight footprint. It’s a level of planning that really paid off — the layout is efficient and future-ready.”

At the heart of the system are five ABB HVC 360 power cabinets, each capable of delivering up to 360 kW across four outlets, supported by seven ABB Terra 180 kW dual-outlet chargers. Together they provide 34 concurrent charging points and a total site capacity of around 3 MW.

The system uses dynamic power allocation, shifting energy between outlets depending on demand — for example, prioritising a single bus for a fast top-up while throttling others back.

“This is the first time we’ve deployed our HVC 360 solution in New Zealand,” said Bailey Gorst, ABB National Sales Manager – eMobility.

“That makes it hugely significant. It demonstrates what large-scale depot electrification looks like in a New Zealand context, with a unique combination of gantry charging, a complex brownfield site, and smart load management.”

Singer is ABB’s licensed electrical contractor and agent and Gorst says having a partner like Singer is critical.

“They know the equipment, understand the site constraints, and make sure the solution works on the ground, giving operators’ confidence. As ABB’s licensed contractor and agent, they bring the expertise needed to deliver this successfully,” she says.

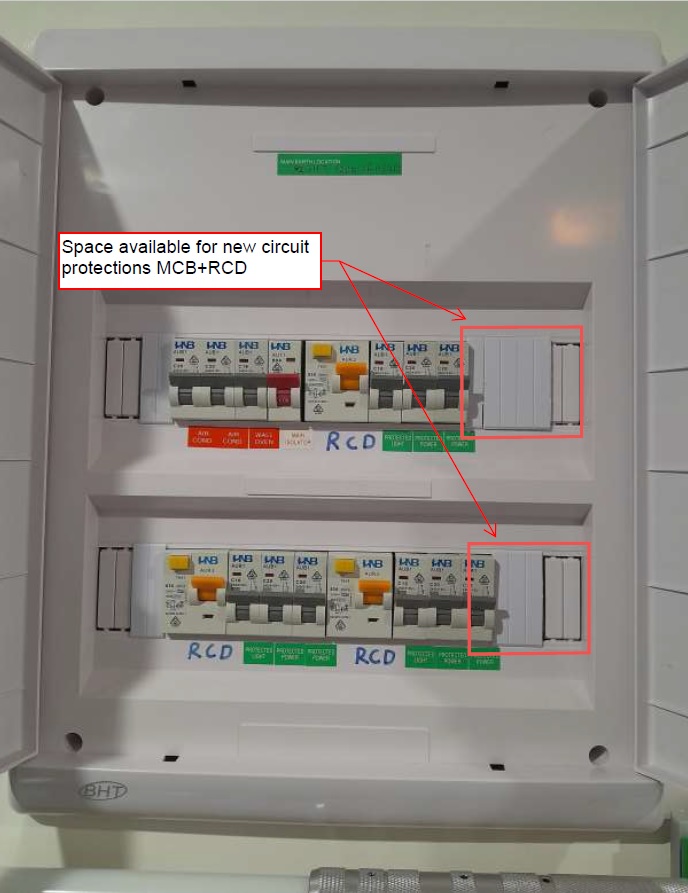

Power to the depot is supplied via two 750 kVA transformers configured with a bus tie for redundancy. Load is balanced using Evis Z software, which ensures the depot remains within its power limits while still delivering fully charged buses every morning. The smart system avoids costly over-capacity charges and builds resilience into daily operations.

Wood says the level of collaboration across partners was another highlight of the project.

“For me, the biggest satisfaction is delivering a high-quality product on time and building strong relationships along the way. Kinetic, ABB, Auckland Transport — everyone pulled in the same direction. Glenfield is proof that you can take a very constrained site and still deliver world-class electrification.”

Auckland Transport’s Director of Public Transport and Active Modes, Stacey van der Putten, said Glenfield’s upgrade is central to the city’s Mission Electric programme.

“Right now, Auckland has more zero emission buses than any other city in Australasia. The addition of these 31 new buses, and the associated electric infrastructure, will help us achieve a fully zero emission bus fleet by 2035. These new buses will be used on a range of Auckland Transport routes, including routes 82, 923 and 924, which will be entirely operated by zero-emission buses from later this year.”

The Glenfield project builds on Kinetic’s other electrification sites across Auckland, including New Lynn, Panmure, Māngere and their City depot. Together, these five locations help put the city at the forefront of cleaner public transport, supporting AT’s interim target to reduce operational emissions by 50% by 2031.

Kinetic is New Zealand’s leading operator of zero-emission buses, with more than 320 ZEBs across 10 electrified depots nationwide. The company employs more than 4,500 people through its Kinetic Urban, Go Bus, Johnston’s and SkyBus brands.

Singer Electric brings unique expertise to the Glenfield project, having managed the only megawatt-scale charging installations completed in New Zealand to date. With a history of delivering complex electrical and transport infrastructure, Singer has built a reputation as the go-to project manager for large-format EV charging. The company’s ambition is to remain at the forefront of this transition, applying its specialist knowledge to ensure that depot and fleet operators can adopt new technology with confidence.

“Electrification at this scale is still new for New Zealand, and Singer is proud to be setting the benchmark. Glenfield shows what’s possible, and our ambition is to support more businesses in making the step to clean, renewable solutions for their fleets,” Wood said.

(ends)

FAST FACTS: Kinetic’s Glenfield Bus Depot Electrification

- 31 new zero-emission buses joining the Auckland network

- New Zealand’s first large-scale overhead gantry bus charging system

- Gantry carries 20 overhead charging outlets; buses park diagonally for easy access

- Total charging capacity: 34 buses at once – the largest and most space-efficient charging site of its kind in NZ

- ABB technology: 5 × HVC 360 power cabinets (up to 360 kW each, 4 outlets per cabinet), 7 × Terra 180 kW dual-outlet chargers

- Total site capacity: ~3 MW with dynamic power allocation

- Power supply: 2 × 750 kVA transformers with bus tie redundancy

- Load management: Evis Z software balances demand to stay within site power limits

- Partners: Kinetic (owner/operator of the depot), Auckland Transport, ABB (hardware), Singer Electric (project manager)

- Network impact: Kinetic’s 174 ZEBs operating across 5 electrified depots (68% of Auckland’s fleet), means that Auckland now has the largest zero-emission bus fleet in Australasia. And Nationally, 320 ZEBs operating across 10 electrified depots.

- Targets: AT aiming for 50% operational emissions reduction by 2031 and a fully zero-emission bus fleet by 2035

- Kinetic footprint: 320+ ZEBs nationwide, 10 electrified depots, 4,500+ employees